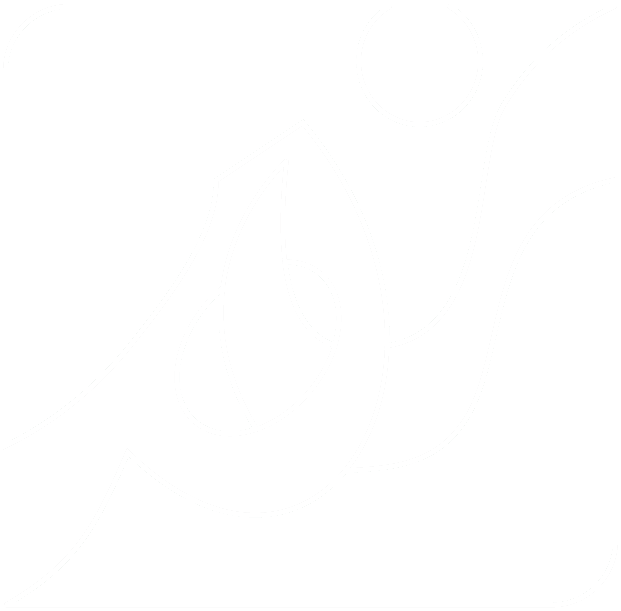

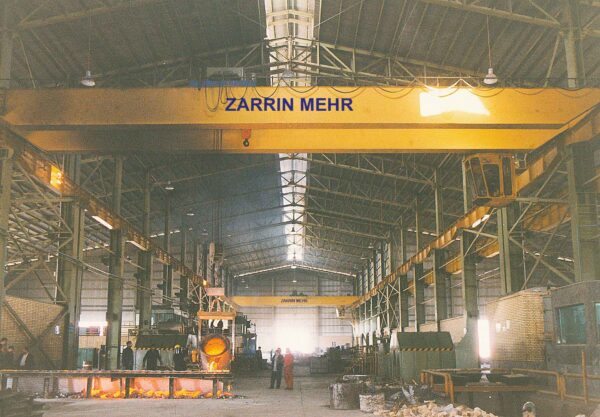

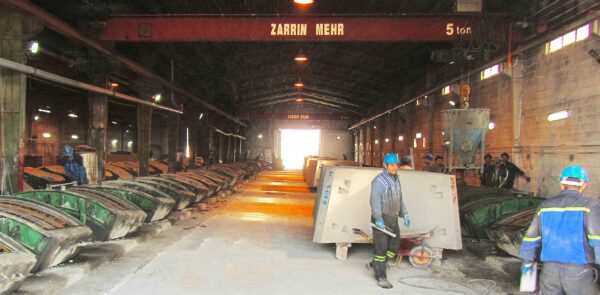

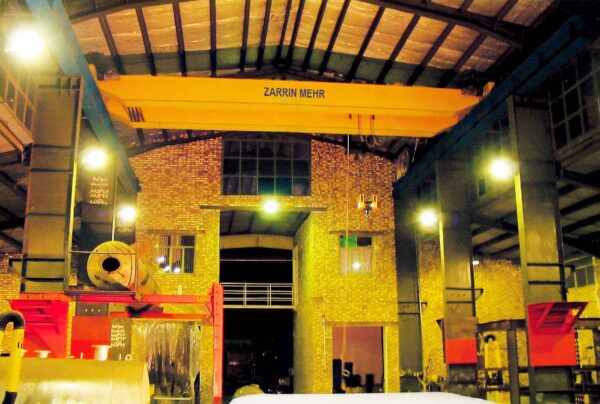

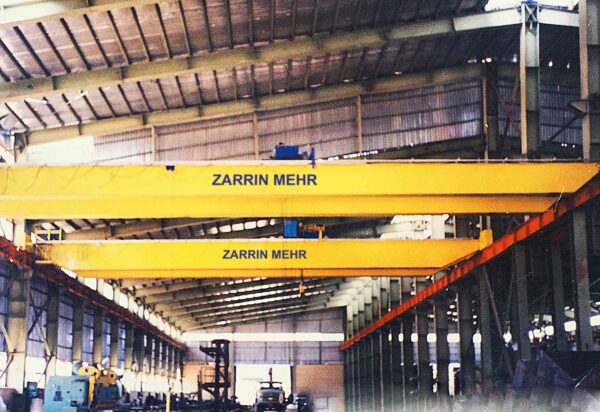

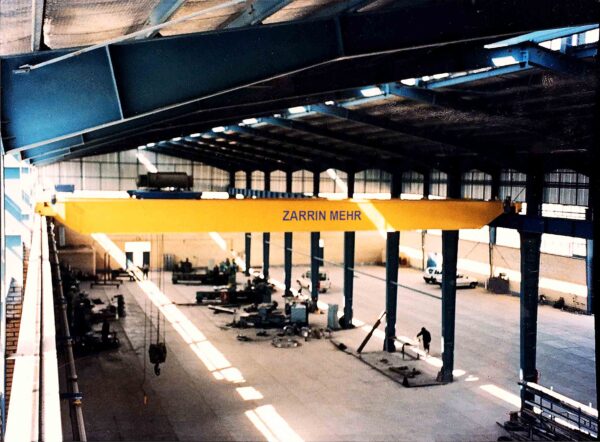

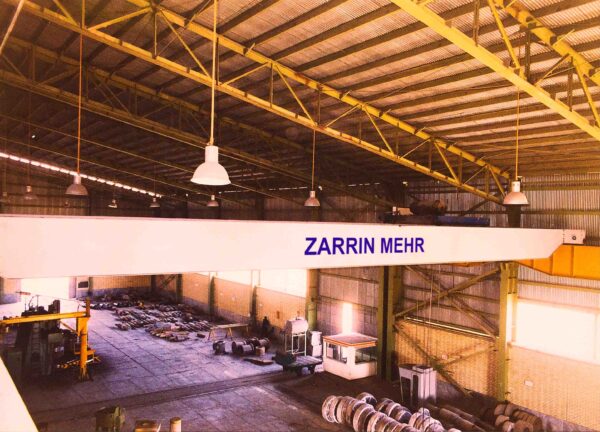

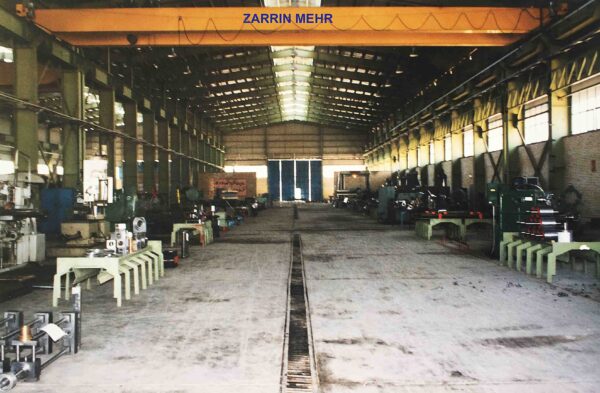

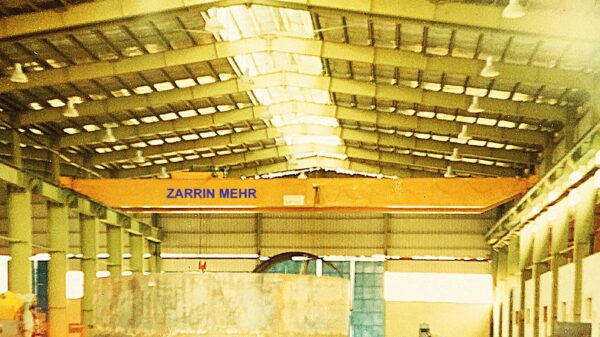

An overhead crane, also known as a bridge crane, is a type of crane found in industrial environments for lifting and moving heavy loads across a horizontal plane. Overhead cranes consist of parallel runways with a bridge beam that spans the gap between them. A hoist, the lifting component of the crane, travels along the bridge to lift and move materials. Overhead cranes are commonly used in manufacturing plants, warehouses, and other settings where heavy or bulky items need to be moved from one location to another.

Main Components of an Overhead Crane:

- Bridge: The main horizontal beam that connects the two runways and moves along them. The hoist and trolley are mounted on the bridge.

- Runways: These are the parallel rails or beams that support the bridge. They are usually attached to the walls or columns of the building or are free-standing structures.

- Hoist: This is the mechanical unit that performs the lifting and lowering of the load. It is mounted on a trolley that travels along the bridge.

- Trolley: This is a unit that houses the hoist and can move along the length of the bridge to position the hoist above the load.

- End Trucks: These are located on either side of the bridge and contain wheels that allow the bridge to move along the runways.

- Controls: These could be a wired pendant, a control panel, or a wireless remote control that the operator uses to control the movement of the crane, hoist, and trolley.

- Electrical Components: These include motors, wiring, and controls that power the movement of the hoist, trolley, and bridge.

- Safety Features: These may include overload sensors, emergency stop buttons, and other devices to ensure safe operation.

Types of Overhead Cranes:

- Top Running Cranes: In this design, the crane runs on rails located on top of the runway beams. They are typically used for heavy-duty applications.

- Under Running (Underhung) Cranes: The crane runs on rails located on the underside of the runway beams. These are usually for lighter-duty applications and allow for more flexibility in building design.

- Single Girder Cranes: These cranes have a single bridge beam. They are generally used for lighter loads and shorter spans.

- Double Girder Cranes: These have two parallel bridge beams and are used for heavier loads and longer spans.

- Monorail Cranes: These are a simplified type of overhead crane consisting of a single beam with a hoist and trolley. They are used for specific, linear movement of goods.

Advantages:

- Efficiency: Overhead cranes can move heavy materials quickly and efficiently, improving workflow.

- Safety: Properly operated, these cranes can move heavy and potentially dangerous materials safely, reducing the risk of workplace accidents.

- Space-Saving: Because they are mounted overhead, these cranes free up floor space that can be used for other operations.

Safety Precautions:

- Regular inspections and maintenance are crucial for safe operation.

- Operators should be trained and certified.

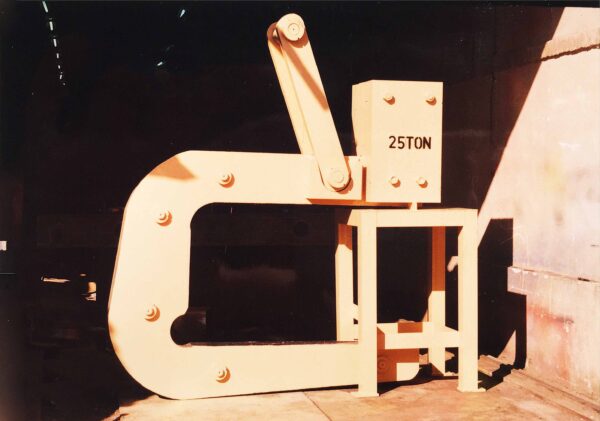

- Always ensure the crane is rated for the load you intend to lift.

- Make sure the load is securely attached before lifting.

Overhead cranes are versatile and essential pieces of equipment in many industrial settings. As with any machinery involving heavy loads, they must be operated with care and attention to safety protocols.