Jib cranes are a type of lifting equipment commonly used in various industries for material handling and lifting applications. They consist of a horizontal jib (or boom) that is attached to a vertical mast or column, which is then mounted to a wall or floor. The jib can rotate around the vertical axis, allowing for the movement of loads within a specific area.

There are several types of jib cranes, including:

- Wall-mounted jib cranes: These cranes are attached directly to a wall or other vertical structure, allowing for the jib to extend and rotate. They are ideal for areas with limited floor space or where floor-mounted cranes are not practical.

- Freestanding jib cranes: These cranes are supported by a floor-mounted column, allowing them to be installed in areas where there is no suitable wall support. Freestanding jib cranes can be moved and repositioned if needed.

- Pillar-mounted jib cranes: Similar to freestanding jib cranes, pillar-mounted cranes are supported by a column, but the column is mounted to the floor and overhead structure, providing additional stability and capacity.

- Articulating jib cranes: These cranes have a unique two-arm design, which allows them to reach around obstacles and provide more precise positioning of loads. They can be wall-mounted or freestanding.

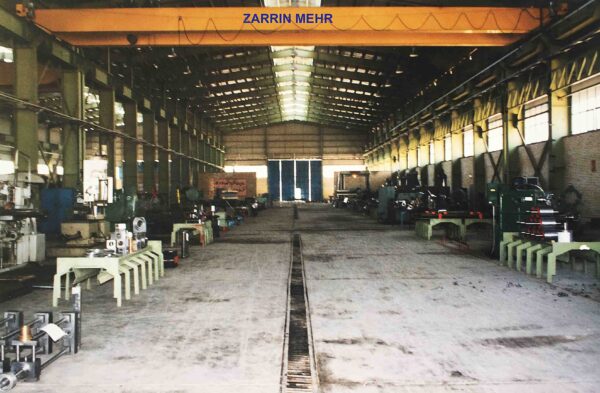

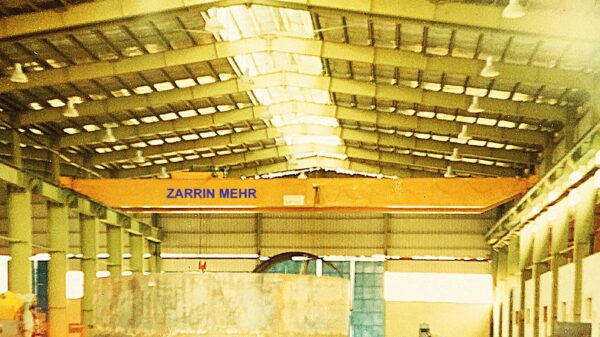

Jib cranes can be operated manually or powered by electricity, pneumatics, or hydraulics. They are used in various industries, including manufacturing, warehousing, construction, and shipping, for tasks such as lifting heavy materials, loading and unloading trucks, and assembling large components.

When selecting a jib crane, factors to consider include the required lifting capacity, working radius, and height clearance, as well as the available space and mounting options. It is essential to follow safety guidelines and perform regular inspections and maintenance to ensure the safe operation of the crane.

Different aspects of jib cranes, their applications, and safety considerations:

- Jib crane components:

- Jib: The horizontal beam that extends from the vertical support and is responsible for supporting the load.

- Vertical support: This could be a wall, column, or pillar, providing the necessary stability for the jib crane.

- Hoist and trolley: A hoist is the lifting device that raises and lowers loads, while a trolley allows the hoist to move along the jib. They can be operated manually, electrically, pneumatically, or hydraulically.

- Rotation mechanism: This allows the jib to rotate around the vertical axis. The range of rotation depends on the crane design and can be up to 360 degrees.

- Applications:

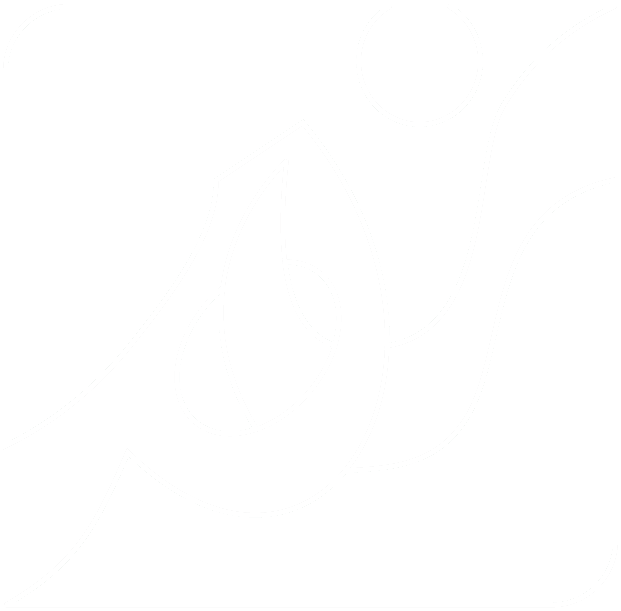

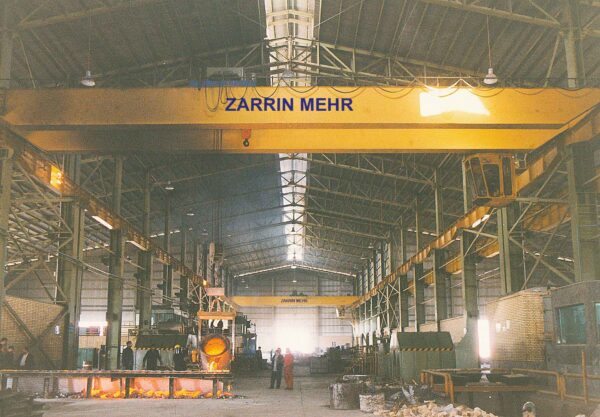

- Manufacturing: Jib cranes are used to move raw materials, components, and finished goods within a facility. They can also be used for maintenance tasks, such as replacing heavy machinery parts.

- Warehousing: In warehouses, jib cranes can be used for loading and unloading materials from trucks, organizing inventory, and moving heavy items between storage locations.

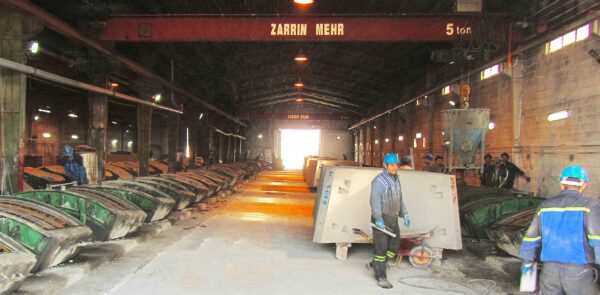

- Construction: Jib cranes can assist in the transportation of building materials, such as concrete blocks, steel beams, and precast sections, as well as the installation of heavy equipment.

- Shipping: In ports and shipyards, jib cranes can be used to load and unload cargo, move containers, and perform maintenance tasks on ships.

- Safety considerations:

- Proper training: Operators should be trained in the safe operation and maintenance of jib cranes. This includes understanding load limits, proper lifting techniques, and emergency procedures.

- Regular inspections: Jib cranes should be inspected regularly to identify and address any potential issues, such as wear and tear, corrosion, and damaged components.

- Load limits: It is essential to follow the manufacturer’s guidelines for maximum load capacity to prevent accidents and equipment damage.

- Fall protection: If operators work at heights while using a jib crane, they should use appropriate fall protection equipment.

- Clear communication: Operators should maintain clear communication with other workers in the area to ensure everyone’s safety during crane operations.

- Proper maintenance: Regular maintenance should be performed to keep the crane in good working condition and ensure its longevity.

By understanding the various components and applications of jib cranes and following essential safety guidelines, these versatile pieces of equipment can be used effectively and safely in a wide range of industries.