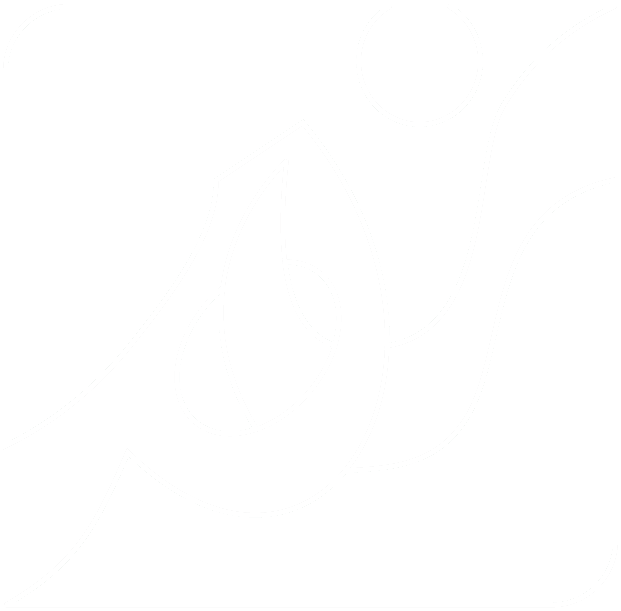

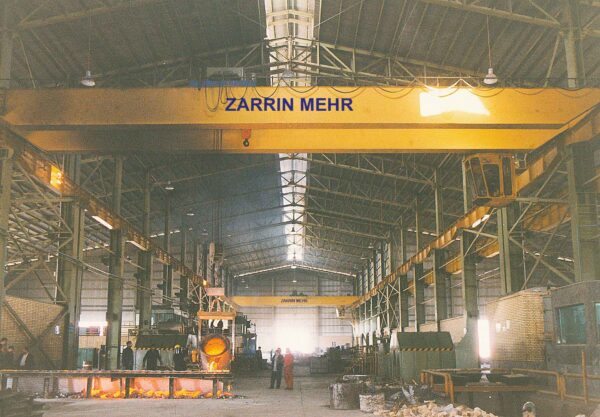

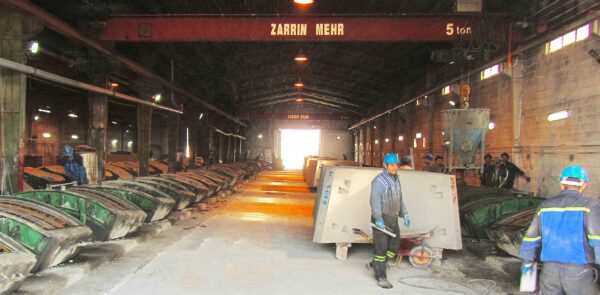

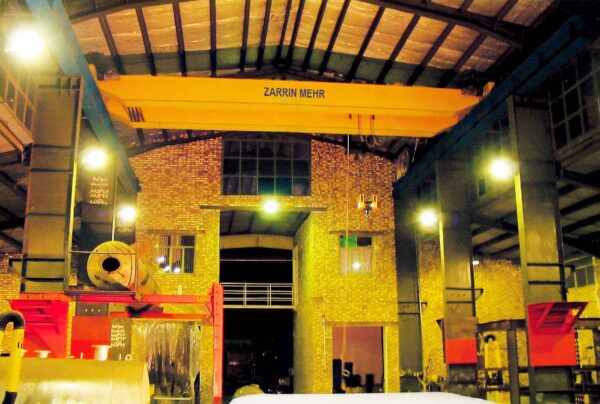

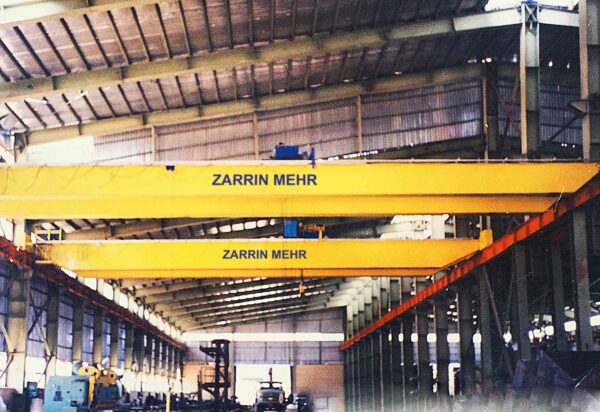

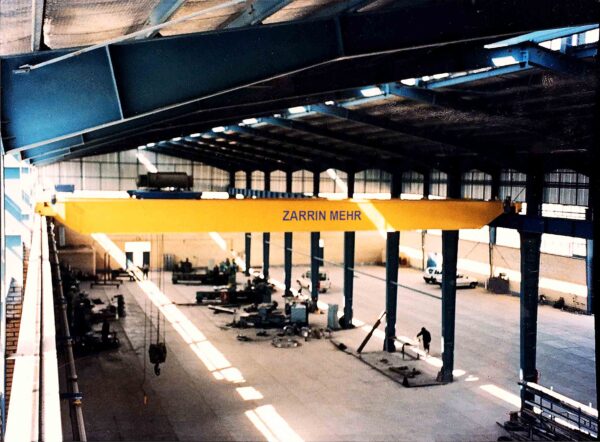

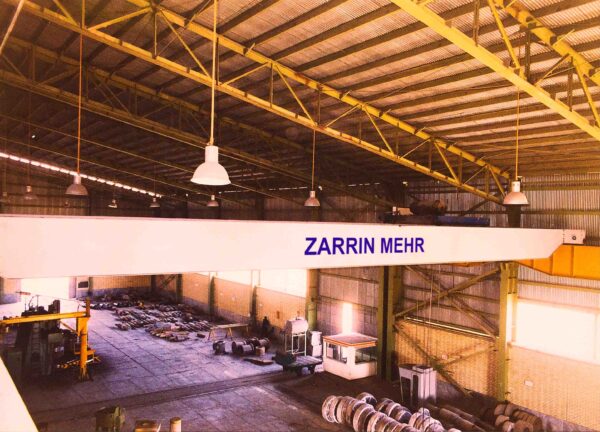

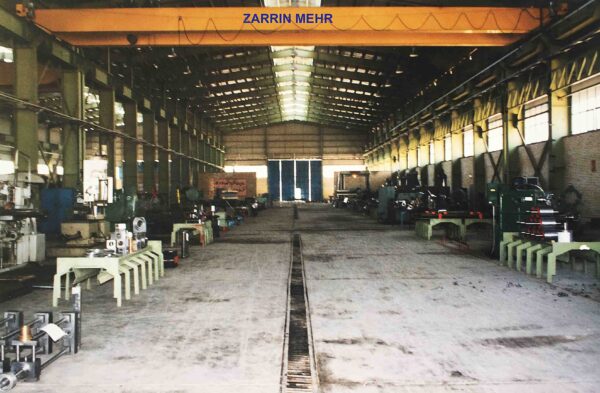

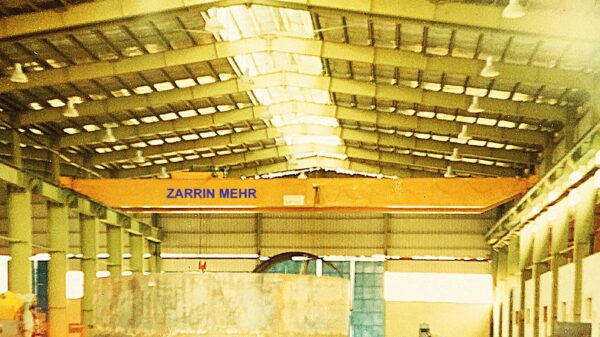

A chain hoist is a mechanical device used for lifting or lowering heavy objects. It operates on a simple principle: manual or motorized pulling of a chain turns a pulley or a set of gears that lifts or lowers the load. The chain hoist is often used in conjunction with other lifting equipment, such as jib cranes, gantry cranes, or overhead cranes, to facilitate the vertical transportation of goods and materials in various settings like workshops, factories, construction sites, and warehouses.

Main Components of a Chain Hoist:

- Lifting Chain: This is the primary component that attaches to the load being lifted. It is made from high-strength metal links.

- Hand Chain or Control: In a manual chain hoist, a separate hand chain is pulled by the operator to activate the lifting mechanism. In an electric or pneumatic chain hoist, this is replaced by a control panel or remote control.

- Gearing Mechanism: This includes a set of gears or pulleys that multiplies the force applied, making it easier to lift heavy loads.

- Hook or Latch: This is the component that attaches the lifting chain to the load. It often has a safety latch to ensure that the load doesn’t slip off.

- Load Brake: This is a safety feature that prevents the load from falling if the lifting mechanism fails or if the chain is released.

- Housing: This is the outer casing that holds all the internal components. It is generally robust and designed to protect the mechanical parts from dust, moisture, and other environmental factors.

- Trolley or Beam Clamp: In some configurations, the chain hoist is mounted on a trolley that moves along a beam, or it may be attached directly to a fixed beam using a clamp.

Types of Chain Hoists:

- Manual Chain Hoists: These are operated by hand and don’t require electrical power. They are generally used for lighter loads and are portable and easy to install.

- Electric Chain Hoists: These use an electric motor to lift or lower the load, making it easier to handle heavier weights and offering the advantage of speed and ease of control.

- Pneumatic (Air-Powered) Chain Hoists: These are powered by compressed air and are commonly used in environments where electrical devices are not suitable, such as chemical plants or other hazardous locations.

Advantages:

- Portability: Chain hoists are generally compact and can be easily moved and installed.

- Simplicity: The design is straightforward, making it easy to operate and maintain.

- Durability: They are often built to be robust and can last a long time if properly maintained.

- Cost-effectiveness: Manual chain hoists, in particular, are less expensive than other types of lifting equipment.

Safety Precautions:

- Always check the load capacity of the hoist before use.

- Make sure the load is securely attached to the hook or lifting attachment.

- Inspect the chain and other components regularly for wear and tear.

- Use proper lifting techniques and guidelines to ensure the safety of operators and bystanders.

Chain hoists are a fundamental tool in various industries for tasks that require the lifting, lowering, or moving of heavy materials.